MECHANICAL TECHNOLOGY: a voice in the chorus of Innovation

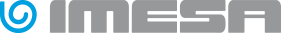

The high spin aseptic barrier washers D2W series by IMESA includes today four models with the following capacities: 18-23-30-55 Kg.

They are robust, reliable and efficient washing machines, built in AISI 304 stainless steel and made entirely in IMESA.

Today we tell the production of the drum, which differs from the drums of standard washing machines for its shape and the typical opening on a side, that allows automatic placement on both sides of the washer, in the infected one for loading and in the clean one for unloading clean laundry.

The drum is originally a closed cylinder, a single steel planking with a portion, corresponding to the opening door, joined to the entire structure through micro-joints; this preserves the rigidity of the workpiece during all processing steps such as bending, folding and welding.

Once all the processing phases of the basket have been completed, the door is assembled: from the raw piece to the closing system, all manufacturing steps take place in IMESA.

The door has an extremely safe locking system, equipped with a safety stop that prevents accidental opening of the drum during the washing cycle.

The D2W series is particularly suitable for laundry operations in hospital clinics, retirement homes and wherever there is a need to treat infected linen through specific cycles of sanitation and paying the utmost attention to the separation of working spaces where you handle infected linen and clean linen.