CLEAN vs INFECTED

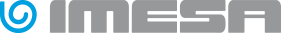

In the previous publication of How we make it? we have deepened the steps that characterize the production of the D2W hygiene barrier washing machine drum.

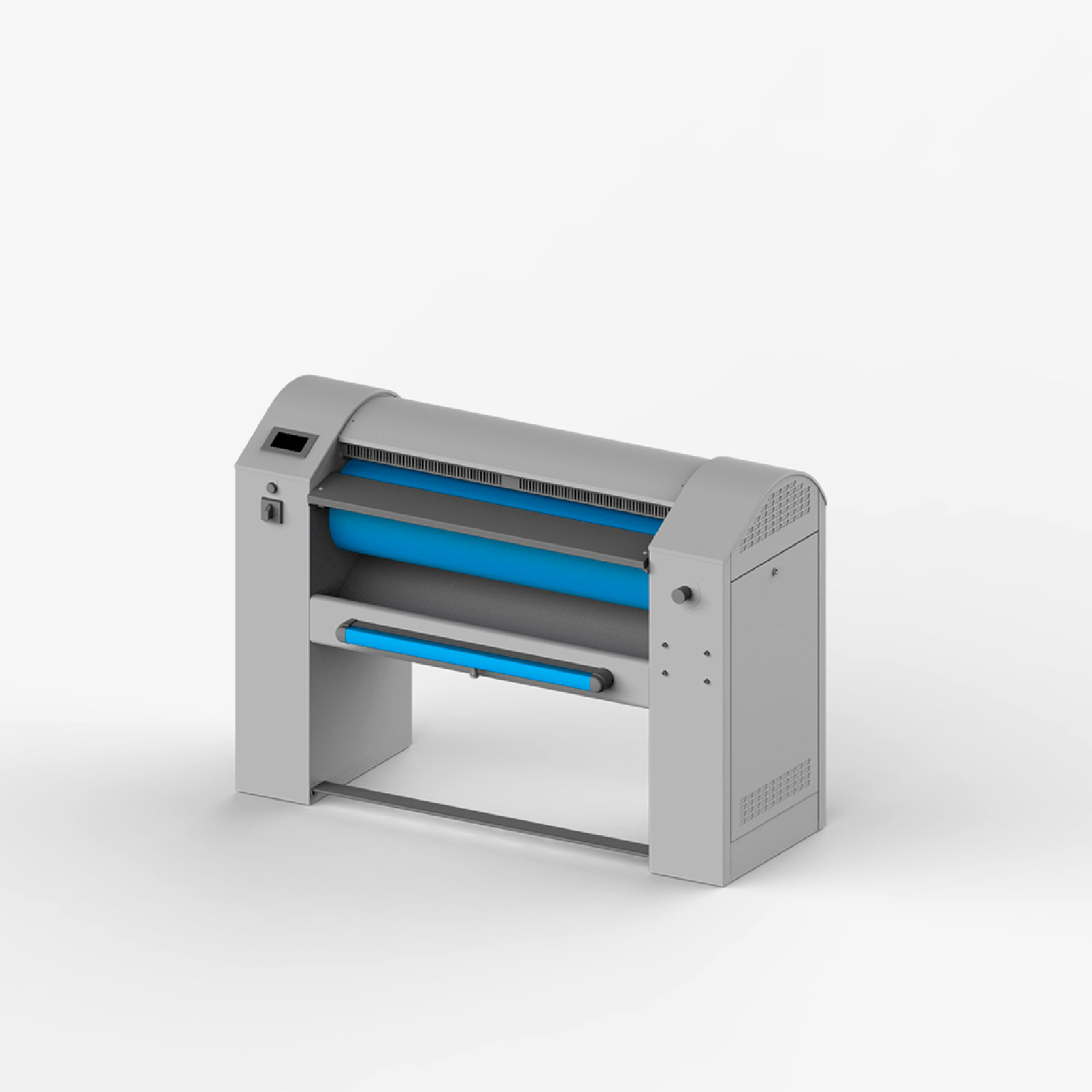

Today we focus on the drum position adjustment on both sides of machine, infected and clean.

We have already talked extensively about the importance of keeping infected laundry separate from clean laundry by creating, possibly, two separate working environments.

D2W aseptic barrier washing machines, with two opening doors on both sides of the machine, fully meet this requirement.

How to manage a single drum in two opposite environments?

The washing machines are equipped with adjustable optical position sensors that perform the function of controlling the position of the drum on both sides. The accuracy of the sensors ensures the correct positioning and therefore the certainty that dirt and clean do not come into contact.

Even in case of lock or cycle interruption it is possible to place the drumm with opening on the chosen side.

The proper installation of the aseptic barrier washing machines is done by placing the machine through a wall or a partition, so that the operator can handle and introduce dirty laundry without contaminating the clean one in any way.

IMESA provides, on request, an aseptic profile kit to close the space between the wall and the washing machine, a guarantee of hygiene and safety for operators and guests.

The IMESA series is characterized by its solid and robust construction and ease of use and is particularly recommended for hospitals, clinics and social care in general.