Washers and duvets, a successful test - turn to read -

How to combine a laboratory test with a free service for IMESA colleagues?

This is how it all started, from an idea of the IMESA Lab and R&D team.

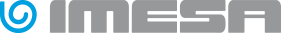

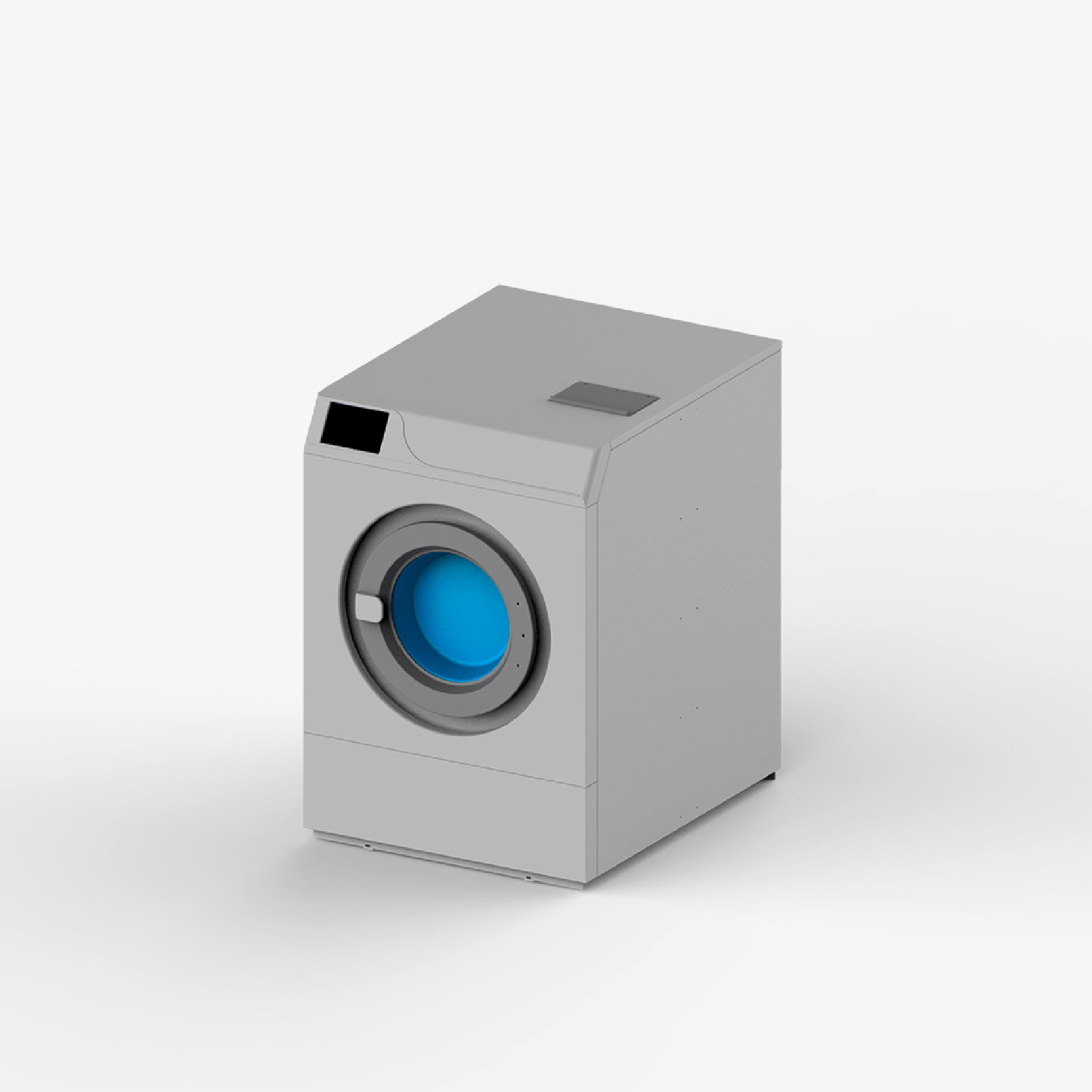

This is how we recreated in our lab an indoor laundry consisting of 1 high-spin washing machine LM23 model with IM11 touch screen and 1 tumble dryer ES23 model with IM10 touch screen, to offer to IMESA employees a free washing&drying service for duvets bed, anorks and padded garments.

Among the linen treated there were also large synthetic blankets, sometimes used as carpet, of size and volume out of standard, off-standard mats for size and volume.

A very appreciated service at the end of winter season, when it comes time to treat the heavy bed linen before storing it.

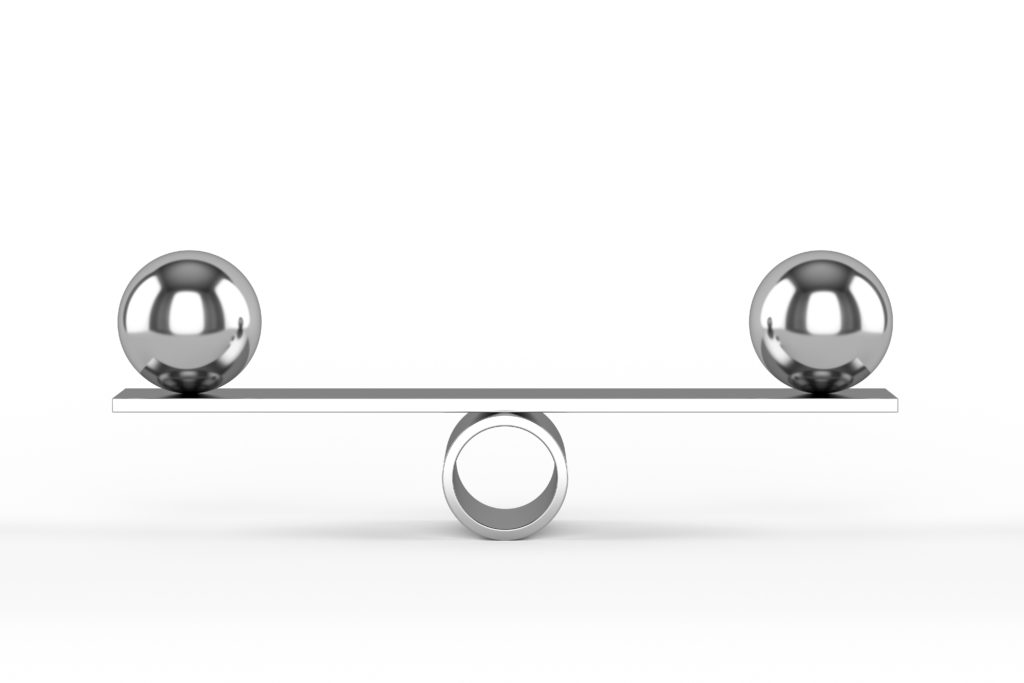

The aim was also to test the machines, especially the washing machine, from the dynamic point of view and measure in particular the efficiency of the spin phase in the presence of linen of considerable volume and weight and different types of fabric.

We know that the declared capacity of a washing machine refers to dry cotton garments. Often, especially in self-service use and in Ho.re.ca sector, the linen volume and the load weight do not respect the declared capacity. This means that it is impossible to complete the final spin and consequently finish the washing cycle.

For over a month, March 6 – April 9, we have washed and dried with the following result:

LM23 high spin washing machine is equipped with IM11 touch screen with firmware release 0.353, available since March 2, 2021.

This release allows greater accuracy in the evaluation of imbalance that occures inside the washer drum during the distribution step.

SMART distribution, controlled by IM11, is able to intercept two validation thresholds:

– “PRIMARY” THRESHOLD (optimal, 1st degree target)

– “SECONDARY” THRESHOLD (2nd degree target)

Previous touch screens in use until 2018, did not manage the imbalance during spin phase.

At the end of this long-term lab test, it was found that the investigated version of IM11 completed 93,70% of the spins predicted in a cycle (intermediate and final) and only 1,26% of the 270 final spins carried out failed, not reaching the correct degree of humidity required for the drying phase.

Faced with this positive fact, we are also working to zero even the minimum percentage of residual error, introducing the possibility of recovering the centrifugal failure by repeating it.

How?

Through the final centrifuge control performed: feature in development that will accompany the next releases.

However, in all spins, be it intermediate or final, IM11 independently increases the load tolerance threshold by modifying the acceptability parameters of the problematic spin allowing an intelligent redistribution of the load and a further unbalanced weight screening.

IM11 constantly talks with a portal that delivers multiple data related to IMESA washing machines connected to wi-fi.

The relevant data emerged from the portal, which concerns machines equipped with the latest version IM11, shows that synchronised washing machines benefit from performance far higher than those that have not been updated.

We invite all our customers to connect the machines to the IMESA portal in order not to miss the opportunities to improve the washing results.

For any further information, we are at your disposal.