Today we enter one of the “sensitive” environments of a manufacturing company like IMESA Spa, the LAB.

Completely redesigned in 2020, the lab, which we like to call “the arm” of Research and Development, has been enriched with a functional Life Test area, a team of great experience and a well-organized machine workshop.

In the laboratory you can breathe research. It is undoubtedly the first critical customer that a product IMESA must deal with.

The IMESA lab team boasts years of training, knowledge but above all experience in the field, maturing the ability to pay attention to even the smallest aspects.

Basically, the IMESA lab team has never lost contact with customers, a strategic source of data and essential information to continuously feed the case studies.

In the workshop the laundry sector is simulated in a few square meters recreating the working environments to constantly improve the performance of the machines.

In the Life Test area we stress the machines to the limit in a short period of time, concentrating in a short time frame the productivity of medium-long-term, to produce the data needed to analyse and prevent the long-term behaviour and performance of machines.

How does the IMESA laboratory work?

We identify and analyze the physical behavior of the machines, and give the most important contribution in the analysis of washing, drying and ironing processes.

Every day we improve the definition of the relationship between machine, process and player experience that is all those who can interact: not only the end user, but also the maintainer, the programmer, the detergent, etc.

Some important inputs also come from the Service team and refer to incorrect machine usage behavior.

In a washing machine, for example, the load variable is of great importance.

The amount of linen that a user introduces into the basket can make a big difference both in terms of washing efficiency and in terms of overall machine performance, especially if the quantity/type of linen does not correspond to a correct choice of the washing cycle.

How do we prevent this kind of problem?

The plus of IMESA is to ensure that a wrong load does not compromise the machine, its operation and safety.This is possible because our washing machines are prepared to elaborate an extended data range to prevent serious problems.

How did we get to this performance?

Analyzing the critical situations experienced by our customers, recreating them and testing solutions to get the best.

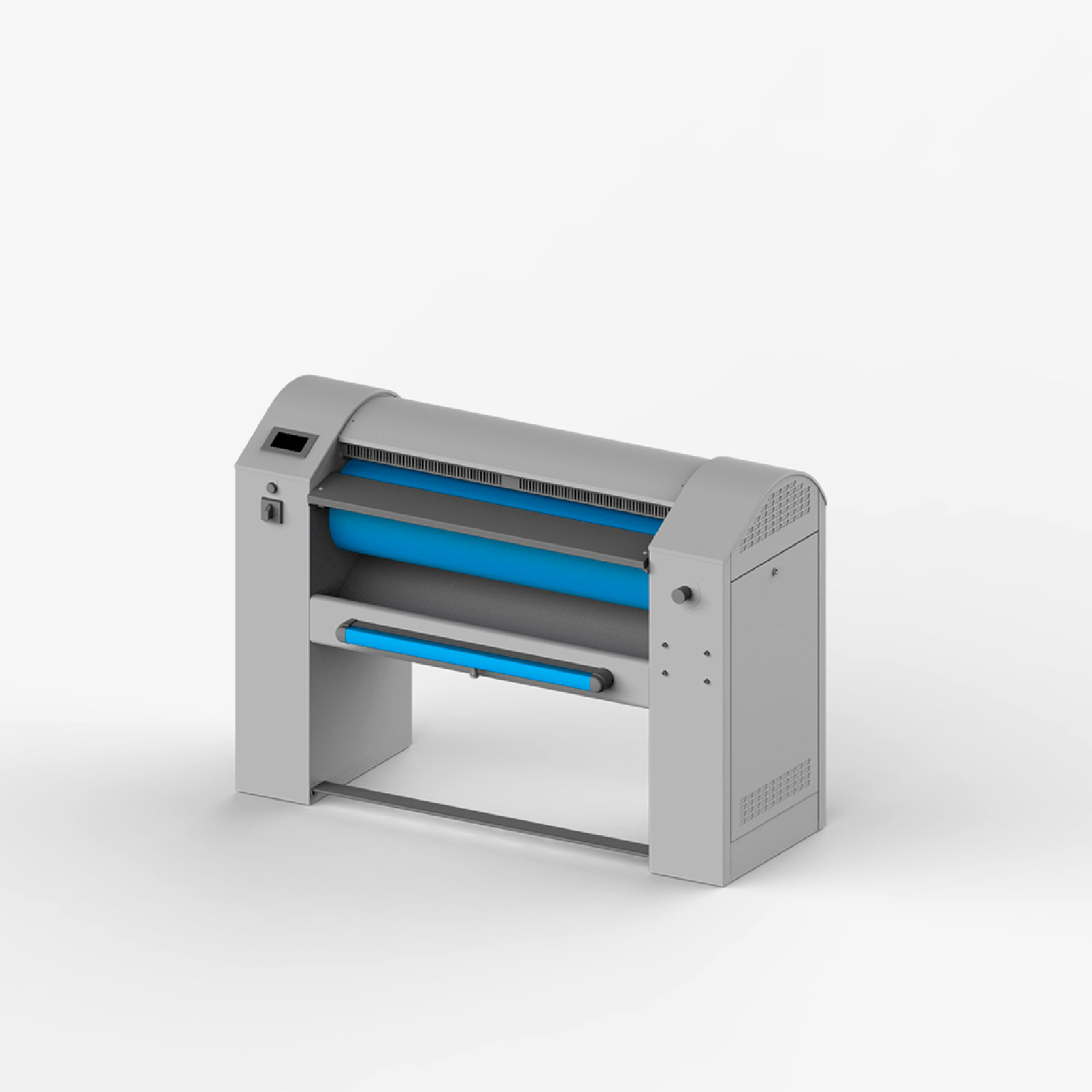

Another laboratory situation is the study of the actions that a user performs in the programming phase of the IM11 computer.

We simulate, for example, the case in which the user proceeds to a wrong programming trying to fix incompatible parameters. The laboratory is able to set up an internship that recreates the exact situation in which the machine is operating, so the simulation becomes relevant to reality and the solution of an anomaly is almost immediate.

IM11 is selective at the programming stage and guides the user not to make mistakes by using presets already compiled, which can possibly be customized by the user according to their needs.

These conditions, dare we say “daily bread”, are simulated and studied in the laboratory with the aim of equipping IM11 with an intelligence always greater to support the customer.

If washing machines are the most fun to stress out, the monotony award is won by the dryer.

Surely the model with more technology is the drying ironers MCM series full optional (automatic feeder, folding, motorized output): a collector of topics worthy to feed various thesis of degree and that obliges our team to multiple “tuning operations” depending on the needs required in users.

But the tasks of a lab do not end under “stressing machines”.

In addition to testing the efficiency of the components, we test new materials and their reaction to chemical or atmospheric agents: corrosion tests on metals, abrasion tests on metals and also on the paints we use.

We deal with statistical AUDIT of the finished product. We take some machines already packed and ready for shipment and we dismantle them again in the lab.

The purpose of this operation is to verify the quality of the finished product ready for delivery and, consequently, the quality of the production process.

Let us not forget the complicated world of Regulations!

In the laboratory we verify the correspondence of our products to the standards to which they are subjected. We conduct a surveillance activity and collaborate with an external laboratory for the elaboration of test reports and other documents necessary for the sale and export.

The satisfaction is to create machines that do not give rise to “remarks” or “failures” during verification.

The IMESA lab is an obligatory reference for all those who need to design, improve and maintain the machines.

A somewhat mysterious place where you can not easily access despite being open to various collaborations.

A space reminiscent of settings and views of science fiction movies from our childhood with mechanical monster and semi-open robots with cables, switches and light everywhere designed for adventurous missions.

Surely the laboratory is a place where a mechanical or electronic enthusiast would like to spend his working time, looking for new or, simply, better technologies with one big goal: to satisfy the customer.