In rest homes and hospitals, it is important to pay great attention to the hygiene of the rooms, beds and all the fabrics used during the daily life and medical activities.

Cleaning and sanitizing are essential especially within structures with fragile or chronic patients.

How can we take proper care of tissues in these specific situations?

Adequate washing machines and specific washes cycles help to reduce the possibility of microorganisms spreading and to limit the spread of infections.

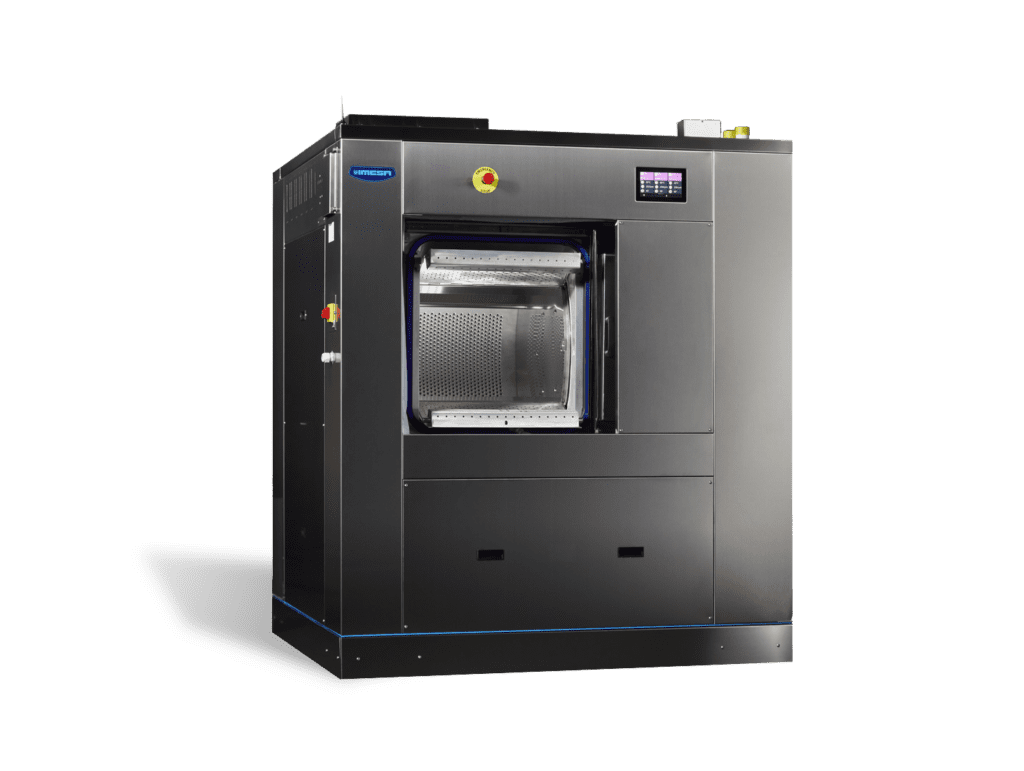

IMESA offers the ideal solution for hospital laundries: the IMESA D2W series aseptic barrier washing machines, designed for maximum hygiene safety in washing processes in hospitals and rest homes, but also in childcare facilities, in clinics and pharmaceutical industries, eliminating the risks of contamination.

How can we make the D2W washing machine the perfect tool for such specific needs?

Through the revolutionary Touch Screen 7″ IM11 mounted on the infected side of the washing machine, thanks to which the total control of washing cycles is achieved, even in Wi-Fi.

To obtain an effective cleaning of tissues, be they stained with blood, organic residues or pharmaceutical products, and achieve a total sanitisation from pathogenic microorganisms responsible for serious infections, it is essential to be able to control the washing cycle in all its characteristics.

With IM11 you can.

With IM11 you get:

- the control of the washing temperature, essential in the treatment of specific stains and in achieving a safe sanitization;

- control of the amount of detergent/disinfectant used, through the correct setting of automatic dosing pumps of the products. Through IM11, the pump programming can be done AT TIME, WEIGHT or SOLUTION %. The detergentist can use a dedicated area in the IoT platform where to store his recipes. The management of the use of detergents, whatever they are, allows a total customization of the washing cycles, making the washing machine aseptic barrier D2W the indispensable tool in hospital laundries;

- automatic management of the amount of cloths introduced. Having to manage large daily amounts of fabrics, it is important the support of a software that allows an effective system of balancing the load linen ;

- predictive maintenance for a perfect operation. IM11 dialogues constantly with technical assistance, providing innumerable data on the washing cycles carried out, any anomalies and wear of the components. This information allows for efficient predictive maintenance to be programmed to ensure that the washing machine is constantly running.

To conclude, we emphasize that the aseptic barrier washing machine D2W complete with IM11 computer translates in optimization of the cycles in every circumstance and in a total and simple integration of the machine with the evolution of chemistry.