Pathogenic micro-organism responsible for serious infections are ubiquituous, invisible but harmful and lurk everywhere.

It is now more necessary than ever to monitor the hygiene of hospital environments.

The safety of care and the well-being of people who stay and work in hospitals or retirement homes is a fundamental and very interesting issue.

For this reason it is essential, within hospital facilities and retirement homes, to manage the laundry service in a professional and safe way. The cleaning of the linen, the uniforms of doctors and nurses and all the fabrics used for medication is of extreme importance for the health of patients and operators.

Incorrect or approximate tissue treatment results in significant costs for the treatment of infections. An appropriate daily tissue sanitisation, on the other hand, is a useful procedure to prevent and contain infectious events.

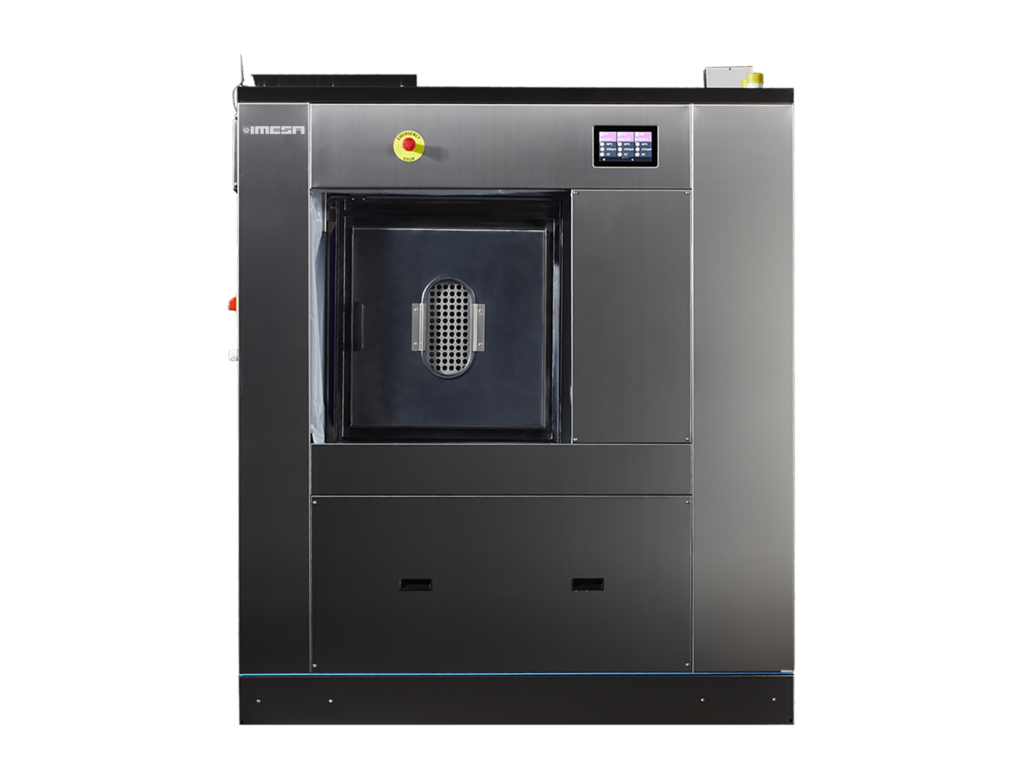

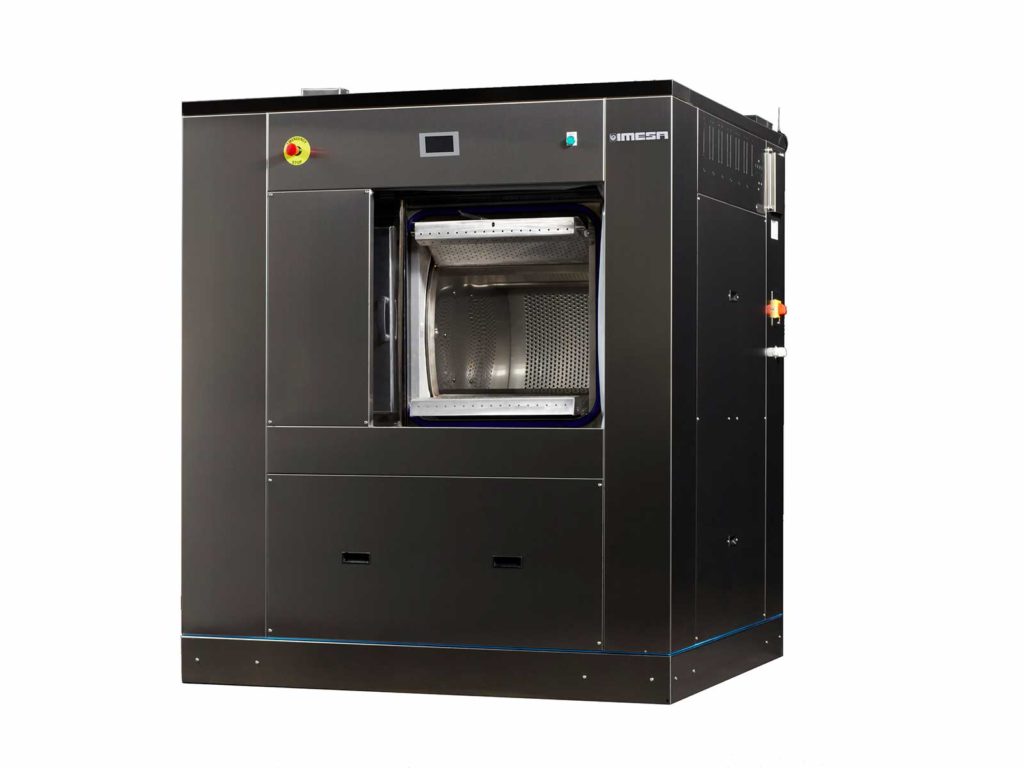

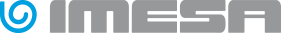

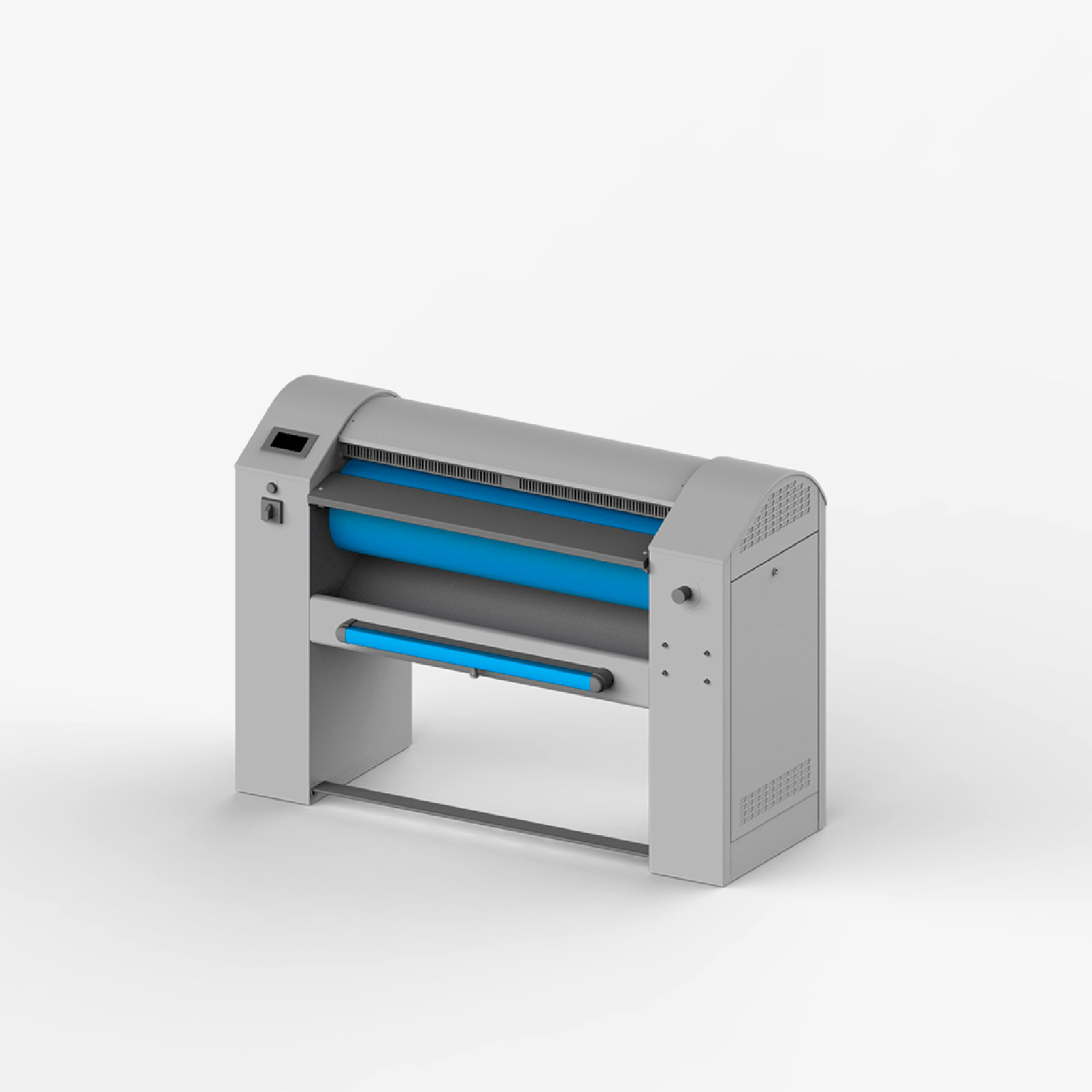

IMESA has created the ideal solution for hospital laundries, IMESA D2W series, the aseptic barrier washing machines.

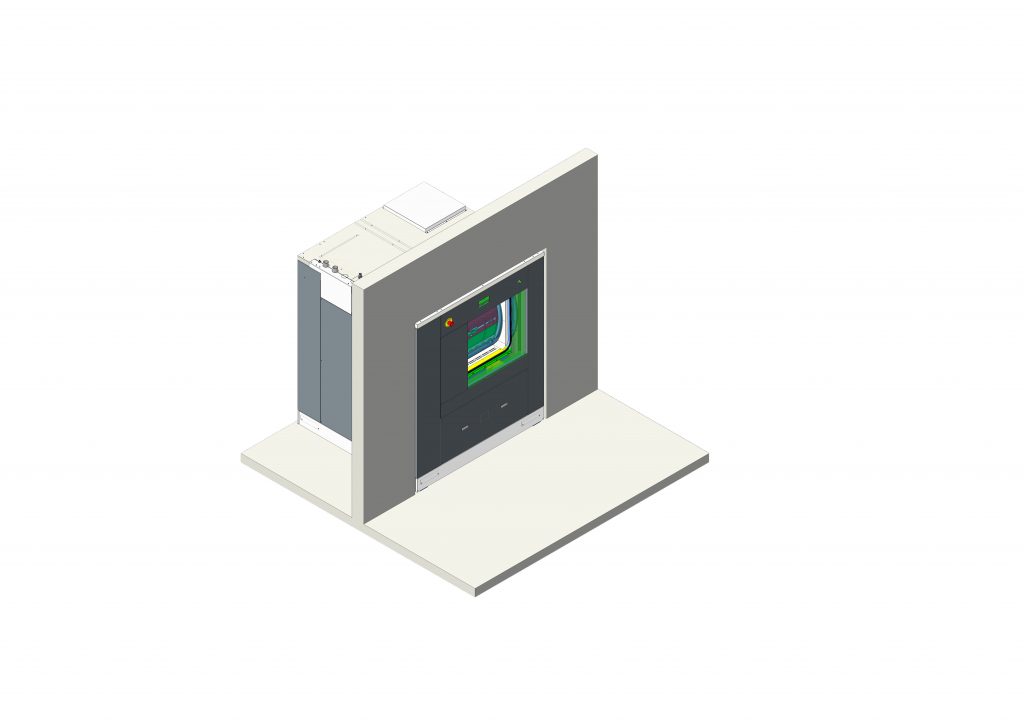

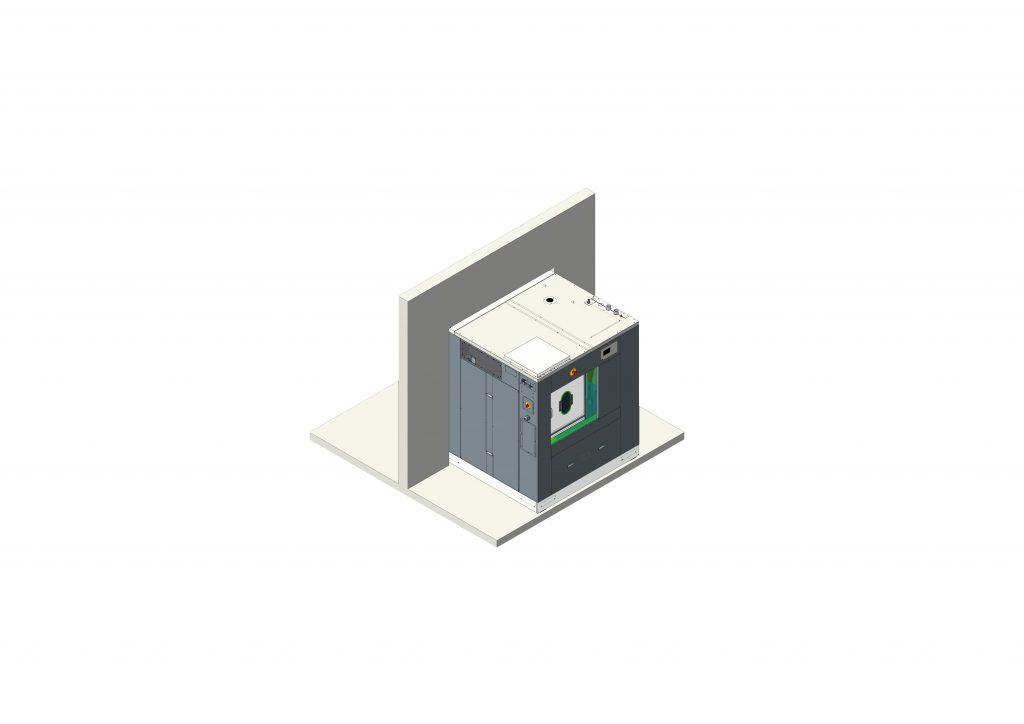

Equipped with two doors, one for loading and one for unloading, the infected linen can be loaded in the dedicated infected linen room and the clean linen can be unloaded from the opposite side, in a separate room. Safety guarantee for operators.

The clean side door is programmed to remain locked until the infected side door is closed and until completion of at least one wash cycle.

The infected side door is programmed to remain locked until the clean side door is closed after unloading operations have been completed.

Programming, adding detergent and maintenance take place from the dirty side, to avoid the risk of contamination and maintain a high level of hygiene.

The control of washing cycles is carried out through the revolutionary IM11 computer that allows to completely customize the programs, adapting them to the multiple needs of stains and fabrics treatment.

Blood stains, organic residues and chemical residues are removed through specific washing cycles, ensuring total sanitisation.

D2W series aseptic barrier washing machines, available with 18-23-30 and 55 Kg capacity, have the following characteristics:

- INNOVATIVE IM11 7” tilted capacitive touchscreen for total washing cicles control , by WI-FI also.

- Infinite washing solutions completely satisfy the needs of disinfection and hygiene.

- Panels in AISI 304 stainless steel, synonym for high quality and endurance.

- 3 alternative heating methods: electric, direct steam or indirect steam for total compatibility with all types of plants

- Electronic control for door opening to avoid all types of contamination.

- IM11 programming touch screen on infected side and second IM10 display on clean side to visualize correct advance of the process, time left and end of program from the sterile room as well.

- Two large opposite doors, separate the loading of the infected linen from unloading the clean linen.

- Practical space-saving SLIDING doors for 30 and 50 Kg models.

- Automatic positioning of the drum for easy opening.

- The washing machine is mounted on a raised platform for maximum ergonomics while loading the linen.

The D2W line is designed and constructed in respect of the EN14065 standard which defines a management system able to provide and appropriate level of microbiological quality according to the use of the fabric and based on the Risk Analysis and Biocontamination Control (RABC) system assessment.

Create a comfortable and healthy environment is indispensable to ensure a high standard quality of assistance and to reach:

– Maximum hygiene

– Maximum standards of cleanliness

– Maximum programming flexibility

– Maximum washing efficiency

– Maximum machine reliability