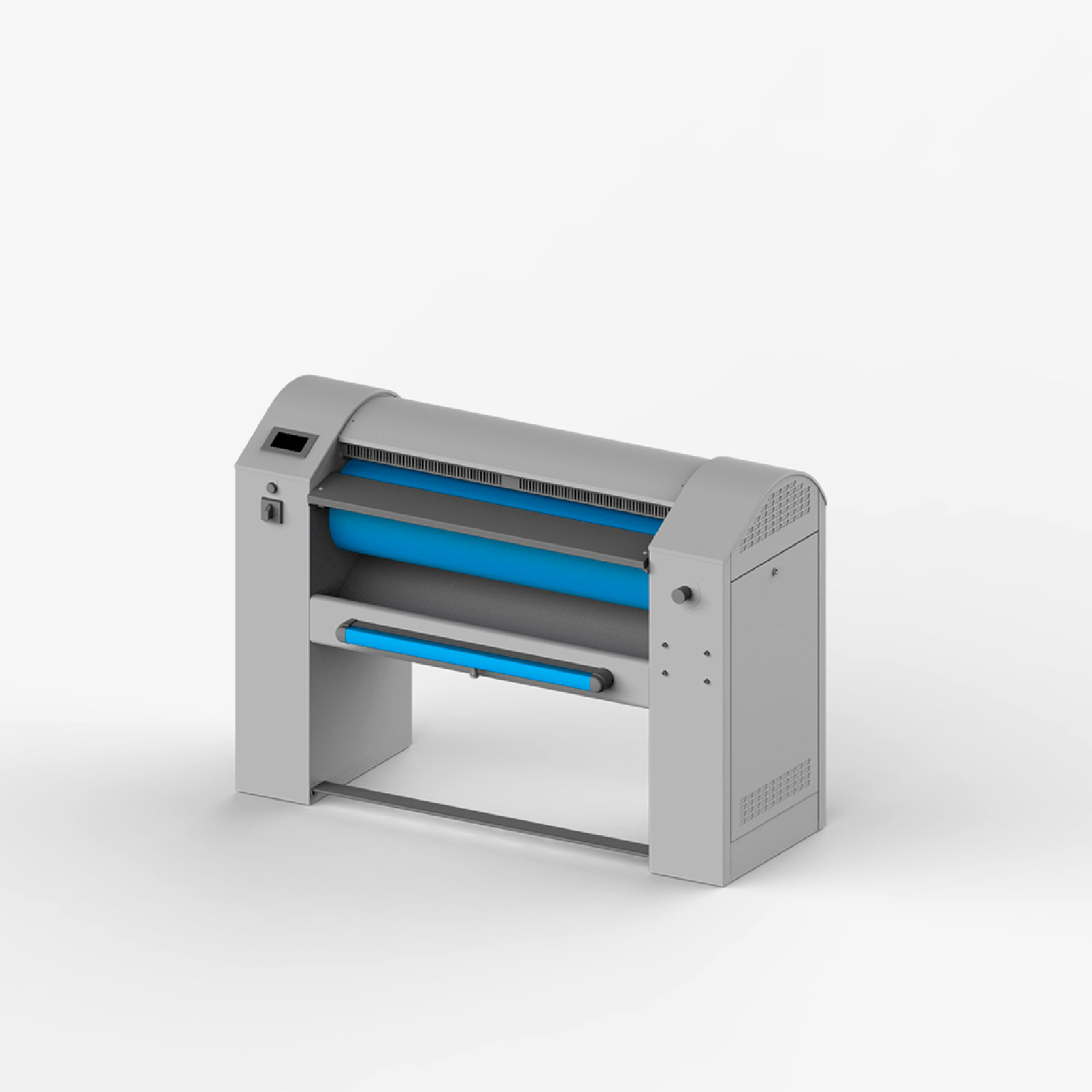

- 3 heating methods: electric, steam, gas

- Automatic speed/temperature compensation: the speed of the roller is set automatically according to the temperature, facilitating the operator’s work and guaranteeing top quality results.

- System cooldown: saves energy and helps preserve the ironing belts.

- Available with motorised linen exit on two sides: faster ironing, higher productivity and more than one operator.

- The linen can be ironed on two independent lines, with the possibility of configuring the type of fold: single, double or none.

- Available with suction feed table for perfect fabric feed, enabling a single operator to iron and fold even large items.

- The version with gas heating guarantees uniform heating of the roller and considerable energy savings, thanks to the particular arrangement of the internal fume circulation.

IM10 computer touch screen for easy programming and monitoring of drying cycles

Like a real tablet, the IM10 touch screen has the same intelligibility, ergonomics and potential as a computer.

Memorisation of infinite ironing programmes

Parameters can be modified during the cycle

IMESA MCM series 502 mm diam. drying ironers are available with 2500 mm, 2800 mm and 3200 mm roller.

The linen remains in contact with the roller for 82% of its circumference perimeter

Available in BASIC version with front/back MOTORISED OUTPUT, FOLDER and automatic FEEDER.

Models with automatic FEEDER and FOLDER are equipped with PLC control with 128 ironing programs.

IM 10

Discover the innovative touch-screen interface

| NOMEX feed and ironing belts, resistant to very high temperatures. |

| In the drying ironer with folder, the safety windows under the feed table enable folding to be controlled in complete safety. |

| The hand safety bar protects the operator from slipping an arm under the roller accidentally. |

| Two emergency buttons |

| MODELLI | MCM 2500 | MCM 2800 | MCM 3200 |

|---|---|---|---|

| Ironing width | 2505 mm | 2715 mm | 3130 mm |

| Ironing width with feeder | 1978 mm | 2190 mm | 2608 mm |

| Maximum length of fabrics for first fold | 3500 mm | 3500 mm | 3500 mm |

| Hourly production* | 62 kg/h | 68 kg/h | 80 kg/h |

| Evaporation* | 31 lt/h | 34 lt/h | 40 lt/h |

| Rotation Speed | 1-6 mt./min. | 1-6 mt./min. | 1-6 mt./min. |

| Ironing Humidity Required | 50% | 50% | 50% |

| Humid Air Drain | 100 Ø mm | 100 Ø mm | 100 Ø mm |

| Smokes Drain (Gas Version) | 100 Ø mm | 100 Ø mm | 100 Ø mm |

| Basic machine and with motorised EXIT dimensions: WxDxH | 3414x1358x1708 mm | 3610x1358x1708 mm | 4027x1358x1708 mm |

| Machine dimensions with OUTPUT, FOLDER and INTRODUCER: LxWxH | 3413x1655x1708 mm | 3610x1655x1708 mm | 4027x1655x1708 mm |

| Net weight basic machine and with motorised EXIT | 1283 Kg | 1371 Kg | 1522 Kg |

| Net Weight with OUTPUT, FOLDER and INTRODUCER | 1656 Kg | 1730 Kg | 1856 Kg |

| Packing dimensions basic machine or with motorised EXIT: WxDxH | 3420x1100x1868 mm | 3630x1100x1868 mm | 4040x1100x1868 mm |

| Packing dimensions machine with EXIT, FOLD and FEEDER: WxDxH | 3420x1300x1868 mm | 3630x1300x1868 mm | 4040x1300x1868 mm |

| Gross weight basic machine and with motorised EXIT | 1351 Kg | 1443 Kg | 1598 Kg |

| Gross weight with EXIT and FOLD | 1726 Kg | 1804 Kg | 1930 Kg |

| Electric power basic machine | 49,3 kW | 52,9 kW | 61,9 kW |

| Steam power basic machine | 0,7 kW | 0,7 kW | 0,7 kW |

| Gas power basic machine | 0,9 kW | 0,9 kW | 0,9 kW |

| Electrical Machine Power with EXIT | 49,5 kW | 52,9 kW | 61,9 kW |

| Steam Machine Power with EXIT | 0,9 kW | 0,9 kW | 0,9 kW |

| Gas Machine Power with EXIT | 1,1 kW | 1,1 kW | 1,1 kW |

| Electrical Machine Power with EXIT, FOLDER and INTRODUCER | 49,5 kW | 53,1 kW | 62,1 kW |

| Steam Machine Power with EXIT, FOLDER and INTRODUCER | 0,9 kW | 0,9 kW | 0,9 kW |

| Gas Machine Power with EXIT, FOLDER and INTRODUCER | 1,1 kW | 1,1 kW | 1,1 kW |

| Hourly steam Consumption | 100 Kg/h | 110 Kg/h | 125 Kg/h |

| Air compressed consumption (with EA or EB) | 500 lt/h | 500 lt/h | 500 lt/h |

| Air compressed pressure (with EA or EB) | 6 bar | 6 bar | 6 bar |

| Basic machine container 20" - 40" loading plan | 2 - 6 pcs | 2 - 6 pcs | 2 - 4 pcs |

| Machine with EXIT, FOLD and FEEDER container 20" - 40" loading plan | 1 - 3 pcs | 1 - 3 pcs | 1 - 2 pcs |

Please visit our download area to:

Do you like these products?

Back to the products

Discover all the range

Back to Drying Ironers

Discover all the series