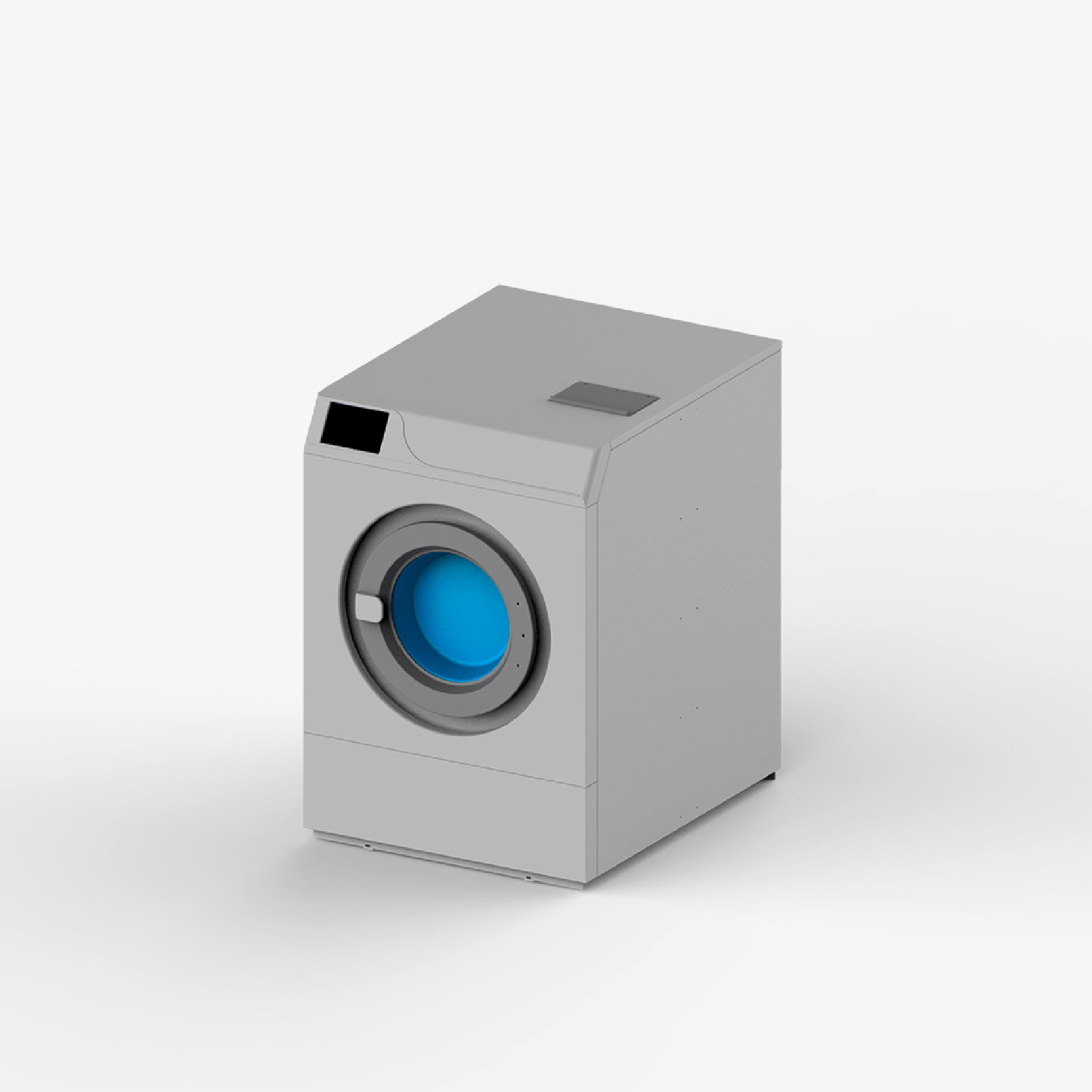

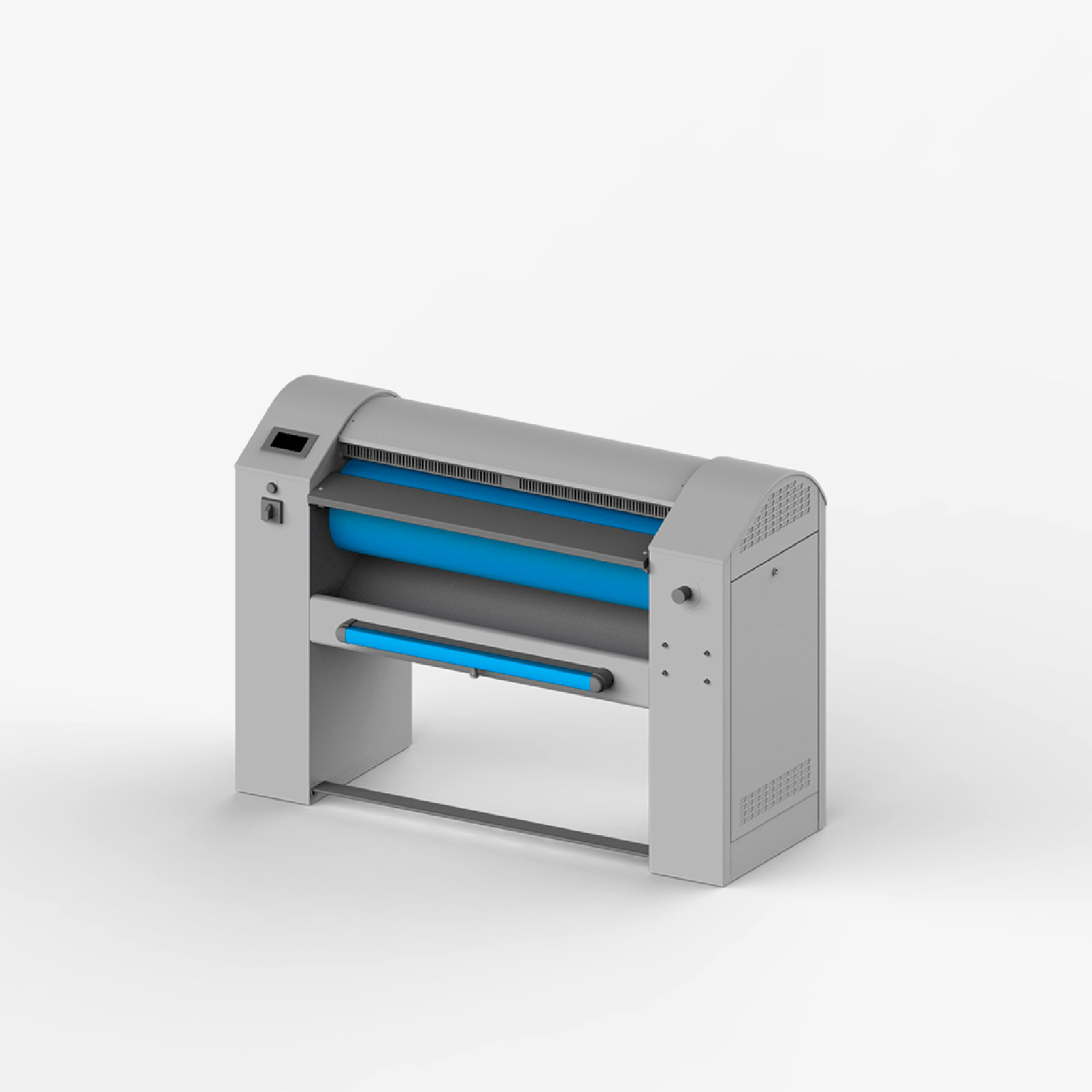

There is no one IMESA machine complete with drum that does not pass through the expert hands of the team formed by Gianluca, Ivica and Jsmaele, who are responsible for managing the first real assembly phase of a washing machine and dryer from 8 kg capacity.

More than 1,000 outer drums and 2,000 drums pass through this team per year, with a daily output of up to 50 closures.

A variety of activities are carried out by them, from the calendering of sheet metal and many other components for production, to the tig welding of platings using the semi-automatic longitudinal welding machine. From making the virole of drums, to riveting, to seaming the bottoms of tanks and drums.

As the outer drums come out finished and ready to be assembled, the drums are taken over by the operator who assembles them to the spider and the shaft. Drum centring is an operation that requires great dexterity and experience: PRECISION is the team’s watchword.

It is in this area that the ‘baptism’ of the machine takes place, i.e. the machine-customer coupling; from this moment on, the machine takes shape, assumes a name and composition until it becomes the finished product desired by the customer.

Gianluca, Ivica and Jsmaele are a young, motivated and coordinated team, an important piece of the big puzzle that is the IMESA family.