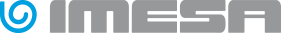

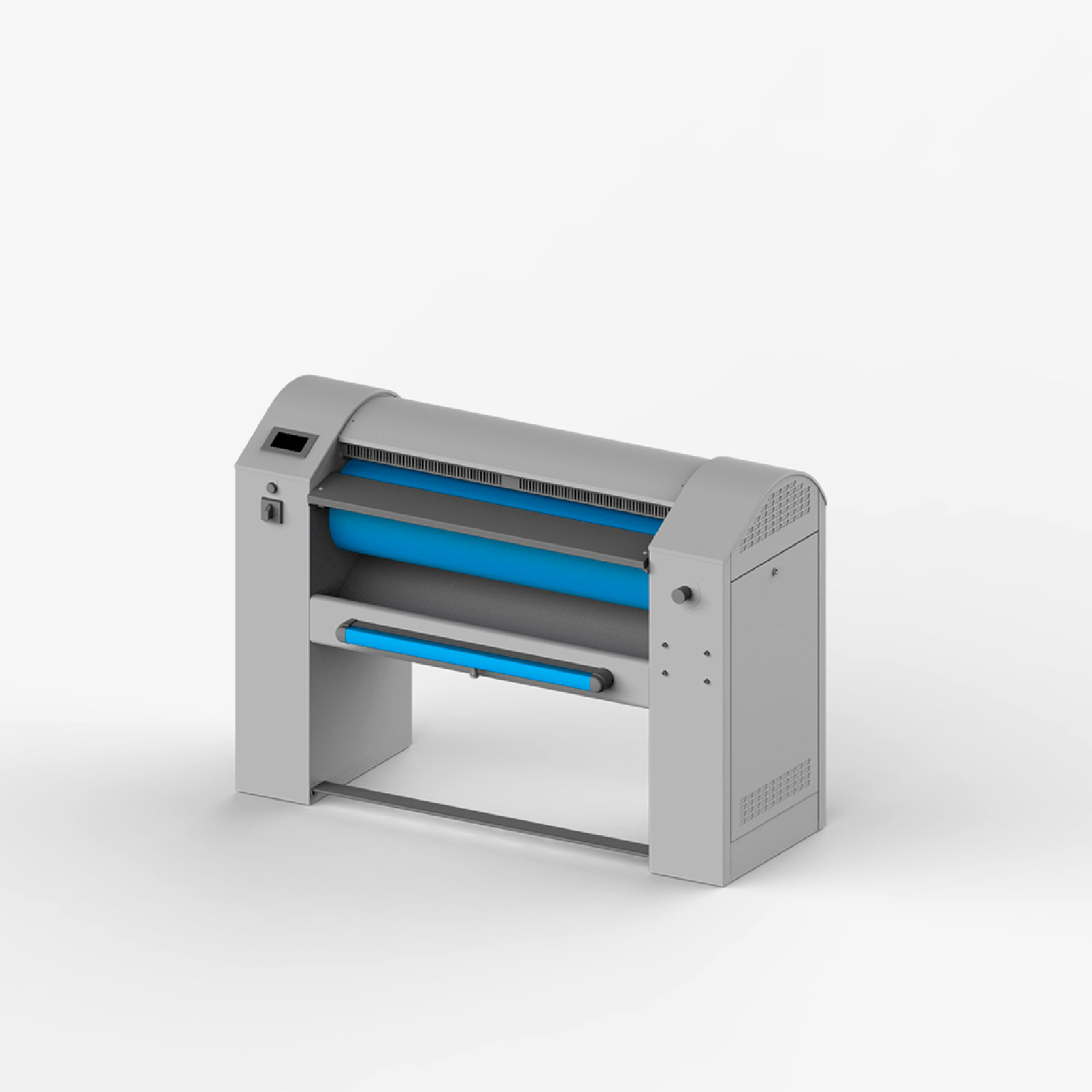

The journey behind the scenes in the production of IMESA’s LM 23 high spin washing machine has come to an end and our washing machine is now a valid work tool for the end customer.

We started from the transformation of the raw material into drum, outer drum and body panels and then passed through the expert hands of a skilled IMESA operator who took care of assembling the outer drum with the drum and the shaft. Then, we moved to the assembly area where the assembly of those components which are the heart of the product is brought to life, the result of intelligent design, accurate workmanship and quality materials.

In IMESA 3 area we witnessed the first phase of in-line assembly of the structural components, followed by the second assembly phase, i.e. the assembly of the mechanical components on the main structure.

The assembly of the electrical panels was a fundamental step in the construction of the LM23 washing machine. Our technicians showed us how they install, connect and test each connection, making sure it’s perfect.

We finally finished the journey through the production of the washing machine in the testing area. Here we witnessed how the quality standards necessary to fully satisfy the customer’s washing needs occur.

Did you miss our episodes on social media? No problem, here is a video that shows the trip. Enjoy it!